Fax:0317-8176016

Tel:17733757654

E-mail:xingshui8339977@163.com

Web:www.hbxsjt.com.cn

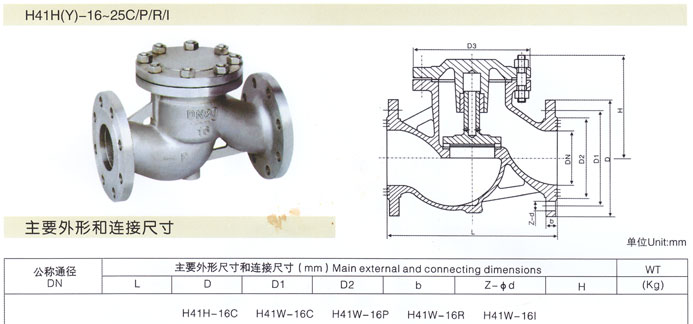

Lift check valve

The lift check valve is a valve that is automatically open and closed by the flow of the medium itself, and is used to prevent the flow of the medium, also known as the reverse stop valve, the one-way valve, the backflow valve, and the back pressure valve. Check valves belong to an automatic valve, whose main function is to prevent the backflow of the medium, to prevent the pump and drive motor reversal, as well as the release of the container medium. Check valves can also be used to supply the pressure to the auxiliary systems that exceed the system pressure. Check valves are mainly divided into swing check valves (rotation of the center of gravity) and lift check valves (along the axis).

Check valves only allow the medium to flow in one direction and prevent reverse flow. Normally this valve is operated automatically, and under a fluid pressure that flows in one direction, the disc opens; When the fluid is in the opposite direction, the self - overlapping disc of the fluid pressure and the disc ACTS on the seat, thus cutting off the flow. Internal thread check valves, butterfly check valves belong to this type of valve,

It includes swing check and lift check valves. The swing check valve has a hinge mechanism, and a gate like valve is free to rest on the inclined seat surface. In order to ensure that each disc to seat the appropriate location, in valve design hinge agencies, so that the disc with enough space of a swing, and real, comprehensive, and the valve seat contact. The disc can be made entirely of metal and can be embedded in the metal with leather, rubber or synthetic coverage depending on the performance requirements. When the swing check valve is fully open, the fluid pressure is almost impervious, so the pressure drop through the valve is relatively small. The valve flap of the lift check valve is located on the seat seal on the valve body. In addition to this check valve can be freely valve movements, like the rest of the cut-off valve, fluid pressure from the valve seat sealing surface lift, medium return led to the disc back to seat, and cut off the flow. Depending on the conditions of use, the disc may be an all-metal structure or in the form of a rubber pad or rubber ring on the disc rack. Like a cut-off valve, fluid through the lift check valve channel is narrow, so the lift check valve through the pressure drop than the swing check valves are bigger, and swing check valves are very few restrictions.

Structure and installation methods

1, the disc lift check valve disc, seat around tunnel axis rotation, due to the channel into a streamline in the valve, flow resistance is smaller than l butterfly check valve, suitable for low velocity and flow not often change the large diameter of occasions, but should not be used for oscillating flow, its sealing performance than lift. Butterfly check valves are divided into single, double, and mostly type three types, which are mainly divided by valve diameter. The purpose is to prevent the flow of the medium from stopping flow or reverse flow, to reduce the hydraulic impact. 2, lift check valve: disc along the vertical centerline of sliding body check, internal thread check valve can only be installed in horizontal pipe runs with the high pressure small check valve disc can be used on the ball. The valve body shape of the butterfly check valve is the same as the globe valve (with the cut-off valve), so it has a larger fluid drag coefficient. The structure is similar to the globe valve, the body and the disc are the same as the globe valve. Disc upper part and lower part of the cover processing has a guide sleeve, Jane Jane disc guide can be freely within the valve light guide Jane, when the downstream of the medium, the disc by medium thrust open, when stop the flow of medium, the disc landing on the hanging on the seat, to prevent medium counter-current role. Direct type butterfly check medium import and export channel direction is perpendicular to the seat channel. Vertical lift check valves with the same direction of the inlet and inlet channel as the seat channel. 3. Lift check valve: check valve revolving around the pin shaft in the seat. Disc check valve structure is simple, can only be installed in horizontal pipe, sealing is better. 4. Lift check valve: valve that slides along the center line of the valve body. The tube type check valve is a new type of valve, which is small in size, light weight and good processing technology. It is one of the development direction of check valve. But the fluid drag coefficient is slightly larger than the swing check valve. 5. Pressure-tight check valve: this valve is used as a boiler feed water and steam cut-off valve, which has the integrated function of the lift check valve and globe valve or Angle valve. In addition, there are check valves that do not apply to pump exit installation, such as bottom valve, spring type, and type Y check valves.

Use and performance

The valve is used for industrial piping to prevent the dielectric current.

Principle and structure description

During the use of this valve, the medium flows in the direction of the arrow.

1. When the medium is flowing in a prescribed direction, the disc shall be turned on by the force of the medium. When the medium reverses, the valve disc and the disc are subjected to the reverse force of the medium, which closes the sealing surface of the disc and the seat to achieve the purpose of preventing the dielectric current.

2. The sealing cover of valve body and disc shall be covered with stainless steel.

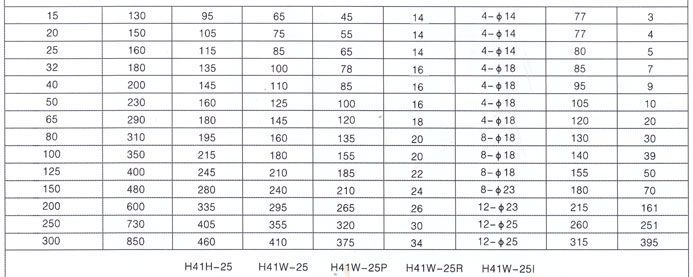

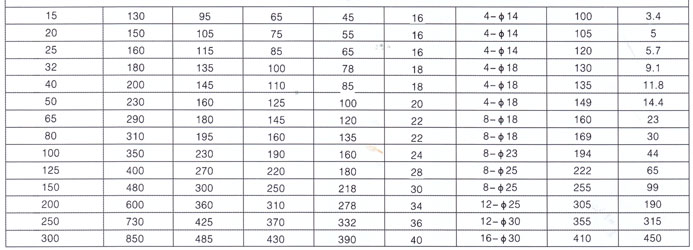

3. The structural length of this valve is in accordance with the provisions of gb12221-1989, and flange connection size according to JB/t79-1994.

Installation and maintenance

1. There must be a blockage at both ends of the valve path, in a dry and ventilated room. If stored for a long time, check against corrosion frequently. 2. Clean the valve before installation and eliminate the defects caused during transportation. 3. Carefully check whether the signs and nameplates on the valve meet the requirements of use. 4. The lift vertical valve check valve shall be installed on the vertical pipe. 5. The elevating horizontal petal check valve shall be installed on the horizontal pipe. 6. In the pipeline, do not allow the check valve to bear the weight, the large check valve shall be independently supported, so that it shall not be affected by the pressure caused by the piping. 7. When installing the check valve, special attention should be paid to the flow direction of the medium, so that the normal flow direction of the medium should be consistent with the direction indicated on the valve body, otherwise the normal flow of the medium will be truncated. The bottom valve shall be installed in the bottom of the pump suction line. 8. The general lifting type check valve shall be installed on the horizontal pipe road, the vertical lift check valve and the bottom valve shall be installed on the vertical pipe, and the medium shall flow from the bottom up. 9, the check valve is closed, will be in the middle water hammer pressure tube, will lead to serious damage to valves and piping or equipment, especially for big or high pressure pipe lines, reason should be the height of the check valve selection is attention.